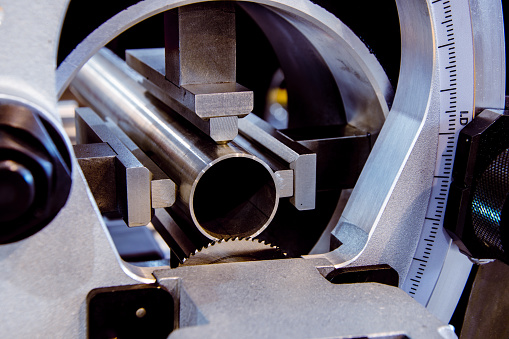

A spinning cutting wheel, knife, Tube Cutter or other tool head is used to cut tubular material into two or more pieces. The fabric is cut into smaller pieces using a cutter blade to cut the tubular material into two or more parts. There are many different power sources available, including hydraulic, pneumatic, electrical, and hybrid systems. In deciding which type of cutter to employ, factors such as the material, the diameter, and the thickness of the pipe or tube are considered.

Features:

Pipe and tube material is cut to the correct shape with a cutting wheel, chain, or other tool head, depending on the application. Hand-held, manually powered pipe and tube cutters are typically curved jaw housing. Once a pipe has been held in place by a cutter’s jaws, an operator can twist the jaws to cut the line in half.

Pipe and tube cutters are used in a variety of applications:

- To design piping systems for both commercial and residential buildings

- For use in fluid transfer systems in industrial plumbing or food processing systems

- For sewage treatment

- The application of liquid or gases

- Heating and air conditioning questions and answers

Specifications:

Many hand-held cutters can cut a wide range of pipe and tube sizes. Pipe and tube cutters that are smaller are typically used for cutting plastic, copper, brass, and aluminum pipes using a steel or zinc blade. Heavy-duty pipe can cut through cast or ductile iron, stainless steel, and large-diameter plastic pipes, among other materials.

It is possible to purchase pipe and tube cutters with shorter or hinged handles to be utilized in locations where pipes are run overhead or in difficult-to-reach areas. In some tube areas, it is not possible to complete a full revolution of the box.

The handle can be hinged to fit the cutting blade around pipes, leaving a tiny gap between the cutting edge and the line. When cutting plastic or PVC pipes, it is common to practice using a rotary tube cutter or an internal cutter.

The presence of outboard rollers on the frame of an in-line rotary cutter helps to keep the blade perfectly aligned with the pipe throughout the operation. Pipe and rotary blades require only 6 to 8 inches of clearance around the pipe to make an accurate cut.

These can be cut through large plastic pipes in drainage ditches and trenches. When cutting a pipe from the inside, internal pipe cutters are used instead of the external pipe and tube cutters to prevent damage to the line.

Internal cutters are tools that have saw-toothed or abrasive blades and handle attachments that can drill into the workpiece. Internal cutters, which are put directly into pipelines, allow operators to cut material quickly and effectively.

Bench orbital pipe and tube cutters are positioned on a bench and can cut through pipe and tube. Their motors are typically equipped with cutting speed regulation, allowing exact control over the cutting process.

It is possible to cut clean pipe material with a single rotation of the circular-toothed cutter. Tabletop pipe and tube cutters can rapidly switch between various pipe diameters and materials. The cut can also be beveled to increase the procedure’s efficiency.